The UK’s motor factor industry is experiencing a significant transition, with electric vehicles (EVs) becoming increasingly prevalent. While this shift presents numerous opportunities for growth and innovation, it also brings to light a pressing issue: the skills crisis. As the industry moves towards a greener future, the need for a workforce proficient in new technologies has never been greater. Let’s dive into the critical aspects of this skills shortage and what it means for the motor factor industry.

The Rise of Electric Vehicles

The UK recently marked a milestone by registering its millionth battery electric vehicle (BEV). This achievement underscores the country’s commitment to reducing carbon emissions and promoting sustainable transportation. The Society of Motor Manufacturers and Traders reported an 8.2% increase in new car registrations compared to the previous year, highlighting a robust growth trajectory in the EV market.

The Skills Gap Challenge

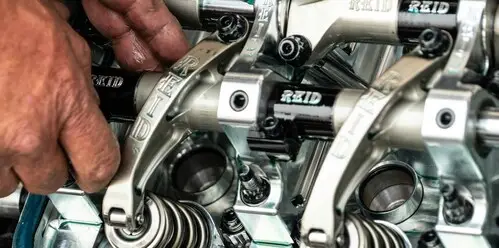

As the motor factor industry evolves, the demand for skilled technicians who can service and repair EVs is surging. Traditional internal combustion engine (ICE) vehicles require maintenance skills different from those of electric cars. EVs involve high-voltage systems, advanced electronics, and software, necessitating new competencies for mechanics and technicians.

The skills gap is exacerbated by the rapid pace of technological advancements in the automotive sector. Many existing technicians need more training and expertise to work on EVs, creating a bottleneck in the industry’s ability to meet growing consumer demand.

Industry Efforts to Bridge the Gap

Acknowledging the pressing nature of the situation., several initiatives have been launched to address the skills shortage. For instance, the SMMT has actively promoted training programs and certifications tailored to EV technology. These programs aim to equip current and future technicians with the knowledge and skills needed to handle the complexities of electric vehicles.

In addition to training, collaboration between industry stakeholders is crucial. Automotive manufacturers, motor factors, and educational institutions must collaborate to develop comprehensive training curricula and apprenticeship programs. This collaborative approach ensures the training is up-to-date and relevant to the industry’s needs.

GSF Car Parts: Leading the Charge

One notable player in the motor factor industry, GSF Car Parts, is making significant strides in addressing the skills crisis. The company is opening a new national centre in Wolverhampton, which will serve as a hub for training and development. This centre aims to enhance the skill set of its workforce, ensuring that technicians are well-prepared to service the latest automotive technologies.

The Road Ahead

While the skills crisis presents a formidable challenge, it also allows the motor factor industry to innovate and adapt. Investing in training and development is necessary and a strategic move that will pay dividends in the long run. By equipping technicians with the skills needed to service EVs, the industry can ensure a smooth transition to a sustainable future.

In conclusion, the UK motor factor industry is at a pivotal moment. The rise of electric vehicles heralds a new era of automotive technology, highlighting the urgent need for skilled technicians. Through concerted efforts in training and collaboration, the industry can overcome this skills gap and continue to thrive in an increasingly electric future.

For more detailed insights and updates on the UK motor factor industry, check out the latest reports from the SMMT and Car Dealer Magazine (SMMT) (Car Dealer Magazine).